Imikhiqizo

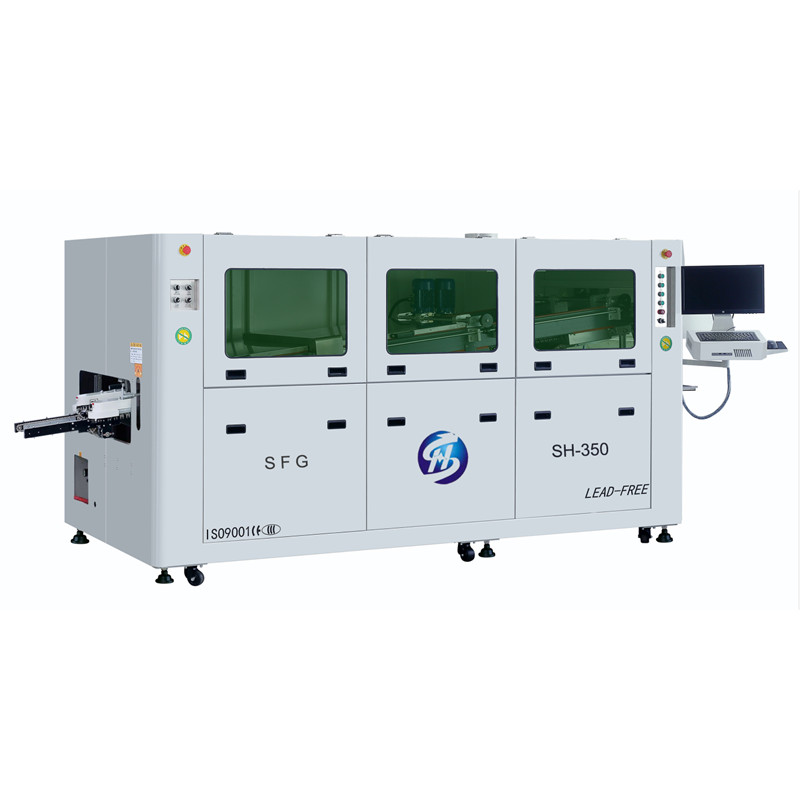

I-SFG Lead Free Wave Soldering Machine SH-350

Ipharamitha

| Imodeli | I-SFG-350 | Uhlobo lwebhodwe le-solder | Isithando somlilo sethayela sesizukulwane sesi-4 |

| Usayizi we-PCB | Ubukhulu.50~350 | Inqubo yokushisisa | Uhlobo lwe-matrix olunamathela ngokuqondile inqubo yokushisa enezinhlangothi ezi-3, ukusebenza kahle kokushisa kungafinyelela ku-95% |

| Ukuphakama kwe-PCB | 750±50mm | I-solder pot tem. | Ithemu yegumbi.~350℃, Ukunemba kokulawula±1-2℃ |

| Isivinini se-Conveyor | 0-2000mm/Min | Lawula ukunemba | ±2℃ |

| I-angle yokushisela | 3~7° | Uhlobo lwezipho | I-FJ claw/L claw/ eyenziwe ngokwezifiso |

| Ukuphakama kwezingxenye | Ubukhulu.120mm | I-Flux | Imanuwali |

| Ukuphakama kwegagasi | 0-18mm | Indlela yokulawula isikhathi | I-PID+SSR |

| Inombolo yamagagasi | 2 | Ukulungiswa kobubanzi | Imanuwali (ejwayelekile)/Ekagesi (Inketho) |

| Ubude bokushisa | 1800MM | Ukungeza i-flux | Okuzenzakalelayo |

| Inombolo yokushisisa | 4ukushisa kwesiteji | Ukugeleza kwe-flux | 10 ~ 100ml/min |

| Isiqondiso | L→R noma R→L | I-spay nozzle | Isinyathelo motor +A-100 |

| Amandla okushisa ngaphambili | 20KW | FLUX kabusha | Ukugaywa kabusha kwephalethi |

| Ukushisa i-Tem. | Ukushisa kwegumbi ~ 250 ℃ | Amandla | I-3Phase 5line 380V/3Phase 220V (Inketho) |

| Indlela yokushisa | Umoya oshisayo | Qala amandla | Ubukhulu.14kw |

| Uhlobo lwe-Solide | LEAD Mahhala | Amandla okusebenza ajwayelekile | Cishe 3-8kw |

| Amandla ebhodwe le-solder | 14kw | Umthombo womoya | 0.4MPa~0.7MPa |

| Isisindo se-solder esiphezulu | Cishe.450kg | Usayizi wobukhulu | 4500*1600*1730(L*W*H) |

| Izinto zebhodwe le-solder | Koqweqwe lwawo lwensimbi | Isisindo | Cishe.1500kg |

Igobolondo Lomshini

| Ukwakheka komzimba | Idizayini yegobolondo elilula, kusetshenziswa uhlaka oluwugqinsi lwephasi yesikwele, ipuleti lensimbi eliwugqinsi elingu-2mm eligobayo ukuze kwenziwe igobolondo, iphansi lomzimba linamasondo ayisiqondiso angu-6, nezinkomishi eziyizinyawo ezingu-6 zokuma nokubeka (izinga lomzimba elilungisekayo nobude);umnyango wangaphambili uyisandiso Ingilazi egobile egobile, idizayini ye-engeli yokubuka ephezulu |

| Isakhiwo somnyango wangaphambili | Isakhiwo somnyango wengilazi oqinile ovalwe ngokuphelele, isicabha sengilazi sifakwe iziphethu zegesi ye-hydraulic embili ukwelula isembozo ukuze kuqinisekiswe indawo enkulu yokusebenza neyokulungisa. |

| Isakhiwo esingemuva | I-Magnet enebhande lesandla isakhiwo esikhiphekayo, isikhala esiphezulu sokulungisa |

| Phezulu komzimba | Isethi yokukhanyisa okungaqhumeki |

| Ukwelashwa kwendawo | Umshini wonke ufuthwe ngomhlophe wekhompyutha (uhlaka lomnyango wengilazi luluhlaza okwesibhakabhaka) |

Spay Izingxenye

| Umbhobho | Ibanga lesifutho liyalungiseka ukusuka ku-20 kuye ku-65mm, ubude benobhobho bungalungiseka ukusuka ku-50 kuye ku-80mm, futhi izinga lokugeleza okuphezulu ngu-100ml/min. |

| Isistimu yomoya | Adopt isihlungi esingenisiwe, ivalvu yokulawula kanye nejoyinti yepayipi, ukucindezela komoya okubonisa idijithali.Ipayipi lomoya elifuthayo lamukela i-asidi ne-alkali ukumelana, ipayipi lomoya le-SMC elilwa nokugqwala |

| Isistimu yokuhambisa umlomo wombhobho | I-stepping motor drive, isilawuli esihlakaniphile se-PLC, isilawuli esihlanganisiwe esinomkhawulo wokushintsha ukusondela kanye neso lokukhanya kwepuleti lokungena, ukutholwa okuzenzakalelayo kwesifutho sokungeniswa ngokuya ngejubane nobubanzi be-PCB. |

| Isistimu yokubuyisela i-Flux | Iphansi lombhobho lenziwe ngensimbi engagqwali egobile futhi yakhiwe njengethreyi equkethe amanzi angcolile kanye ne-flux, engakhishwa futhi ihlanzwe ngokuthanda kwakho. |

| Isistimu yesihlungi se-Flux exhaust | Uhlelo lokungenisa umoya: ifreyimu yesikrini sensimbi engagqwali kanye nesikrini sesihlungi esinezendlalelo ezimbili, kusetshenziswa izici zoketshezi ukuhlunga futhi kubuyise ukugeleza okweqile. |

| Ikhethini lomoya elingalodwa | Ummese womoya womoya uphephetha ukugeleza okwedlulele ngesikhathi sokufafaza ebhokisini lokutakula ukuze uvimbele ukugeleza kungangeni endaweni yokushisa kuqala.Qinisekisa ukuphepha kokukhiqiza. |

| Isakhiwo sebhokisi le-spray | Zonke izakhiwo zensimbi engagqwali, kulula ukuzihlanza nokuyinakekela.Izinga eliphezulu le-anti-corrosion futhi lihlala isikhathi eside. |

Ukushisa izingxenye

| Indawo yokushisa enezigaba ezine | Izingxenye ezingu-1800mm/4 zezindawo zokushisa ezizimele zokulawula ukushisa zinganikeza isikhala esanele sokulungiswa kokushisa, zingashisa kuqala amanye ama-PCB amakhulu ngokuqhathaniswa, imikhiqizo eyinkimbinkimbi kakhulu, izinsalela eziqinile eziguquguqukayo ezingaguquguquki ezingena-rosin ehlanzekile;ukunciphisa ukushaqeka okushisayo kwe-PCB Board, ibhodi le-PCB lishiswa ngokulinganayo, elingathuthukisa ukusebenza kahle kokukhiqiza. |

| Indlela yokulawula izinga lokushisa | Imojula yokutholwa kwezinga lokushisa le-Mitsubishi, ukulawulwa kwezinga lokushisa kwe-PID kunembile futhi kunokwethenjelwa, uhlelo lokubona lwe-thermocouple olungenisiwe, olunomsebenzi we-alamu ongavamile we-thermocouple. |

| Izingxenye zokushisisa | Ukwamukela i-Taiwan Taiwan Exhibition heat element, ukufudumeza okusheshayo, impilo ende, inertia ephansi eshisayo;ukushisa okufanayo endaweni yokushisa. |

| Amandla okushisa ngaphambili | Isamba esingu-22kw |

| Imodi yokufaka | Isistimu yokushisa kuqala yamukela umklamo we-modular wokudonsa oqondile, olungele ukulungiswa nokuhlanza. |

| Preheat ibhokisi ikhava | Yamukela ukubukeka kwe-arc streamline, futhi igcwaliswe nge-Cissr high-density rock wool engenisiwe ukuze ithuthukise umphumela wokulondoloza ukushisa. |

Izingxenye zokuthutha

| Umzila wesitimela ongagugi amandla aphezulu | Isitimela se-aluminium esikhethekile se-SFG sisebenzisa izinga lokushisa eliphezulu nokumelana nokugqokwa, futhi isakhiwo esikhethekile se-thermal compensation anti-deformation telescopic siqinisekisa ukuthi umzila wesitimela awukhubazeki futhi awuwi ebhodini. |

| Ukufana kwesitimela | Idivayisi yokulungisa ububanzi besitimela enamaphuzu amabili okuvumelanisa, ukulungiswa kobubanzi benduku yokunemba okuphezulu, ukunemba kokulungiswa kobubanzi kungaphansi kuka-0.2mm, ukusekelwa kwamaphoyinti angu-6, ukuze ama-rails omhlahlandlela ahambisane futhi ahambisane, alikho ikhanda elikhulu noma elincane. , ukufakwa kwesitimela somhlahlandlela, akudingi ukunqanyulwa, |

| Indlela yokulungisa | Imanuwali |

| Hook kabili | I-SFG ekhethekile engu-1.5MM i-double hook claw (akukho ukuguquguquka, ithini elinganamatheli), ukujiya kwe-splint≦2.5mm (ipuleti elingenayo lixhunywe ngeketango elivumelanisiwe) |

| Iyunithi encane yokusetha isivinini se-C/V | 1mm/min 0-1800mm/min |

| Ibanga lokuchezuka kwesivinini se-C/V | Ukulawulwa kwe-loop kagesi evaliwe ngaphakathi kuka-0-10mm/min |

| I-chain tensioner | Ukungezwani kokulungiswa kwe-Sprocket |

| I-Conveyor motor | I-Taiwan TCG frequency conversion 90W motor, enedivayisi yokuvikela i-overload limiter |

Ibhodwe le-solder

| Izici zesithando somlilo sikathayela | I-nozzle ye-wettability ehlelwe ngokukhethekile (50-400mm), i-flat wave design, indlela yokondla ithini yindlela yokwehlisa ithini, enganciphisa i-oxidation yamalunga e-solder, i-oxide slag iqoqa ngokuzenzakalelayo, kulula ukuyigcina, futhi ayikhiqizi i-tin slag powder emnyama |

| Idizayini ye-oxidation ephansi kakhulu | Isithando somlilo sikathayela esisezingeni eliphakeme, ukuzinza okuhle kokushisa, sisebenzisa isimiso sokuklama ukugeleza kwe-liquid tin, sinciphisa umthelela we-oxidation we-tin, futhi kunciphisa kakhulu i-oxidation ye-tin lapho kushiselwa amabhodi amancane e-PCB. |

| Ukusebenza kwezomnotho | Ilawulwa yi-PLC kanye ne-photoelectric switch to spray wave function, yehlisa imfucuza engadingekile |

| Ngena nangaphandle ebhodweni le-solder | Ugesi |

| Ukuphakama kwegagasi | 0-18mm |

| Wave motor | I-Taiwan TCG high lokushisa motor, ukuguqulwa kwemvamisa ukulungisa ngokunembile ukuphakama kokuphakama, ukulungiswa kwedijithali |

| Izingxenye zokushisisa | Ukwamukela ishubhu yokushisa yensimbi engenasici eyomile eshisiwe eTaiwan, impilo ende yesevisi;Isistimu yokushisa ye-matrix yangaphandle, ukushisa okuphezulu nangaphansi kwesithando somlilo kunembe kakhudlwana, akukho kuqhuma kwethayela, kanye nezimbambo eziningi eziqinisayo ukumelana nokuguquguquka.Yonga u-40% kagesi, cishe ama-kilowatts angama-30 kagesi ngosuku |

Isistimu yokupholisa

| Indlela yokupholisa | Ukusetshenziswa kwefeni ye-centrifugal enamandla amakhulu ukuvuthela phezulu ukuze kuphole kungathuthukisa kakhulu izinkinga ze-cavitation ne-pad peeling ezibangelwa ukwakhiwa kwe-lead-free solder eutectic. |

Lawula isistimu yesofthiwe

| ★ Umsebenzi we-alamu wephutha ozenzakalelayo: kukhona umsebenzi we-alamu ongavamile we-thermocouple, i-alamu yokushisa ephezulu kakhulu futhi ephansi;lapho ukushisa kuqala noma ukwehluleka kwesithando somlilo, ukushisisa kuzomiswa |

| ★ Izinga lokushisa lendawo yokushisa, izinga lokushisa lethayela, isivinini sokuthutha, isenzo sokufafaza, kanye nokupholisa okuphoqelekile kungalawulwa ngokuhlukana. |

| ★ Isilungiselelo sesikhathi seviki elilodwa (Ungasetha amandla okuzenzakalelayo uvule futhi uvale isikhathi kathathu ngosuku, izinsuku eziyisikhombisa ngesonto) |

| ★ Kunezinhlelo ezimbili eziphuthumayo ekhaleni nasemsila womshini, sicela ucindezele ezimweni ezikhethekile neziphuthumayo |