Imikhiqizo

I-Selective wave soldering (S-455)

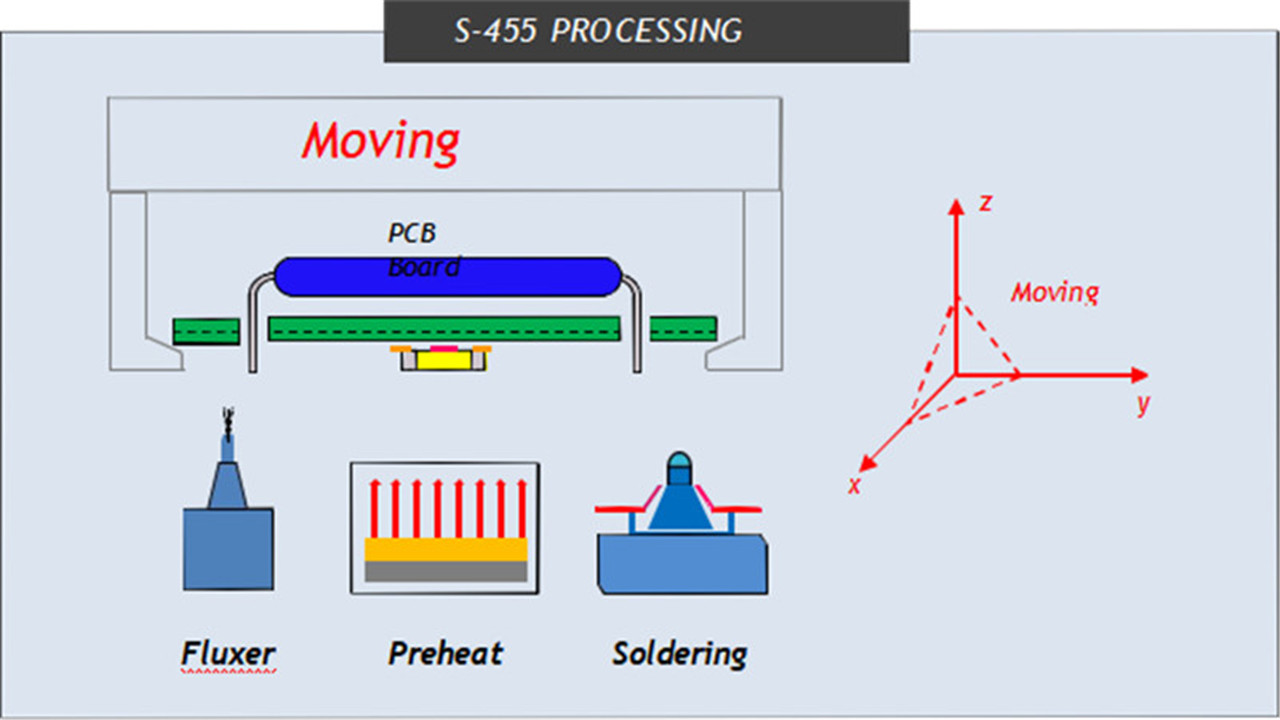

Inqubo yesistimu

I-Pcb yokulayisha imanuwali

I-PCB iya phezulu endaweni yokushisa ngaphambili

Hambisa ngaphezu kwenozzle ye-flux enomzila wokusetha

I-PCB inyakaza ngaphezulu kombhobho wokusoda nge

Ikhipha mathupha

Okunenzuzo

● Konke emshinini owodwa, kuthebula elinyakazayo le-XYZ elihlanganisa ukukhetha okuguquguqukayo nokusoda, okuhlangene nokusebenza okugcwele.

● Ukunyakaza kwebhodi le-PCB, umlomo wombhobho we-fluxer nebhodwe le-solder kulungisiwe.Ikhwalithi ephezulu ye-solder.

● Ingasetshenziswa eceleni komugqa wokukhiqiza, ovumelana nezimo ekwakhiweni komugqa wokukhiqiza.Ukulawula okugcwele kwe-PC.Wonke amapharamitha angasethwa ku-PC futhi alondolozwe kumenyu ye-PCB, njengendlela ehambayo, izinga lokushisa le-solder, uhlobo lwe-flux, uhlobo lwe-solder, izinga lokushisa le-n2 njll, ikhono elingcono kakhulu lokulandelela kanye nekhwalithi yokuphinda iphindwe kalula.

Umshini Standard zihlanganisa

| I-serial | Into | Into | Ubuningi |

| 1 | Uhlelo lokulawula | I-PC & qapha | 1 isethi |

| Bukhoma ngekhamera yokuqapha | |||

| isilawuli sokunyakaza | |||

| 2 | Ithebula le-PCB Motion | Ithebula elinyakazayo le-xyz | 1 isethi |

| i-eksisi efakwe isikulufu sebhola & ne-linear guild rail | |||

| I-axis engu-3 ifakwe i-servo motor nomshayeli | |||

| 3 | Isistimu ye-fluxing | I-valve yejetting eshintshashintshayo engenisiwe | 1 isethi |

| ithangi le-flux | |||

| isistimu ye-pneumatic ye-flux | |||

| 4 | isistimu yokushisa | I-heater ye-IR ngaphansi | 1 isethi |

| 5 | Ibhodwe le-soldering | 15kg umthamo solder ibhodwe, impeller, umhubhe, iseva motor | 1 isethi |

| ukushisa kwe-solder phezu kwesistimu ye-alamu yokushisa | |||

| uhlelo lokulawula ukushisa kwe-solder | |||

| Isistimu yokushisa engaphakathi kwe-N2 | |||

| (Ububanzi bangaphakathi: 4mm x 3pcs, 5mm, 6mm) umlomo wombhobho wesoda ohlomele | |||

| 6 | Isistimu ye-Conveyor | PCB side clampingsystem | 1 isethi |

| 7 | I-chassis yomshini | uhlaka lomshini/ikhava nokudweba | 1 isethi |

Incazelo yomshini

Ingxenye1: Isofthiwe

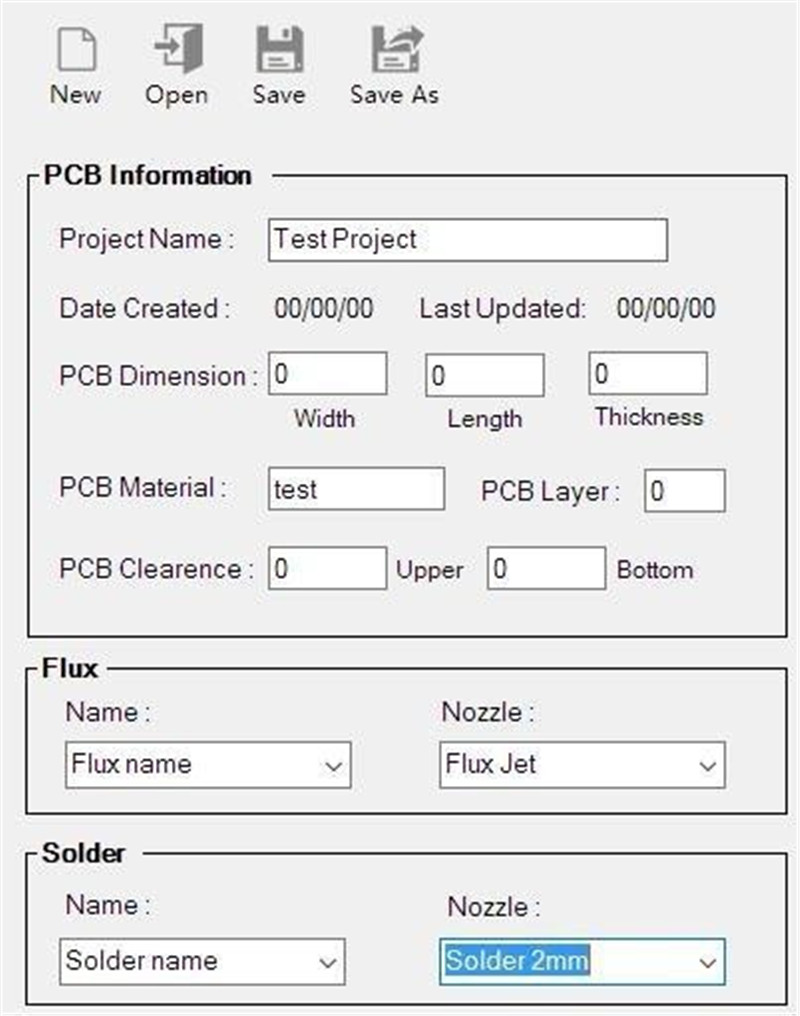

Wonke amasistimu esofthiwe athuthukiswe ngokwesisekelo kusistimu ye-Windows7, enekhono elihle lokulandela umkhondo.

Sebenzisa isithombe esiskeniwe njengesizinda sohlelo lwendlela, isivinini esinyakazayo, isikhathi sokuhlala, isivinini sokunyakaza esingenalutho, ubude buka-Z, ukuphakama kwegagasi njll konke okuhlelelwe isayithi elihlukile lokuthengisa.

Bonisa inqubo ye-solder ngekhamera ebukhoma.

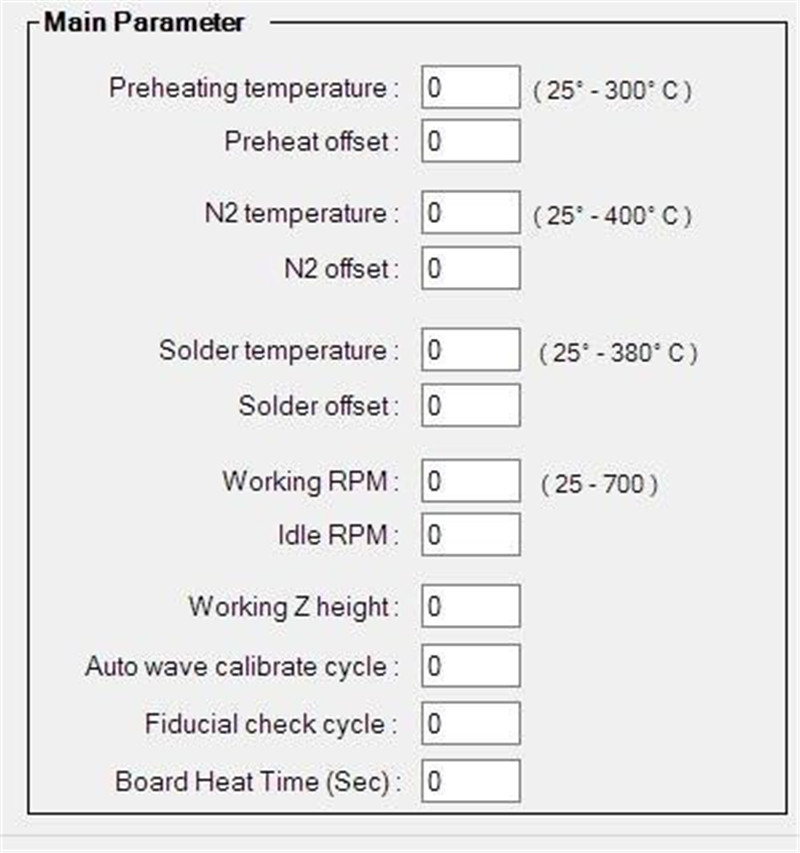

Amapharamitha abalulekile angaphansi kokuqashwa ngokuphelele yisoftware ye-PC, njengezinga lokushisa, isivinini, ingcindezi njll.

Ingathuthukiswa ukuze ibe nomsebenzi wokulinganisa ubude begagasi le-auto, ukuze ihlole futhi ilinganise ukuphakama kwamagagasi ngemva kwayo yonke i-pcb ethile, ukuze kugcinwe ukuzinza okuhle kakhulu kwegagasi.

Ingathuthukiswa ukuze ibe nomsebenzi wokumisa uMark, ukuze uhlole iphuzu lokumaka le-PCB ngemuva kwayo yonke i-pcb ethile, ukuze unciphise isikhundla se-pcb.

Mayelana nemenyu ye-PCB emshinini wokunamathisela, lonke ulwazi luzofakwa kufayela elilodwa.Izobandakanya ubukhulu be-PCB nesithombe, uhlobo lwe-flux esetshenzisiwe, uhlobo lwe-solder, uhlobo lwe-nozzle ye-solder, izinga lokushisa le-solder, izinga lokushisa le-N2, indlela yokunyakaza kanye nokuphakama kwegagasi okuhlobene kwesayithi ngalinye kanye nobude be-Z njll. Lapho ikhasimende lithengisa i-PCB efanayo, lingathola ulwazi olugcwele. mayelana nokuthi kwenziwa kanjani emlandweni, futhi kulula ukulandelela.

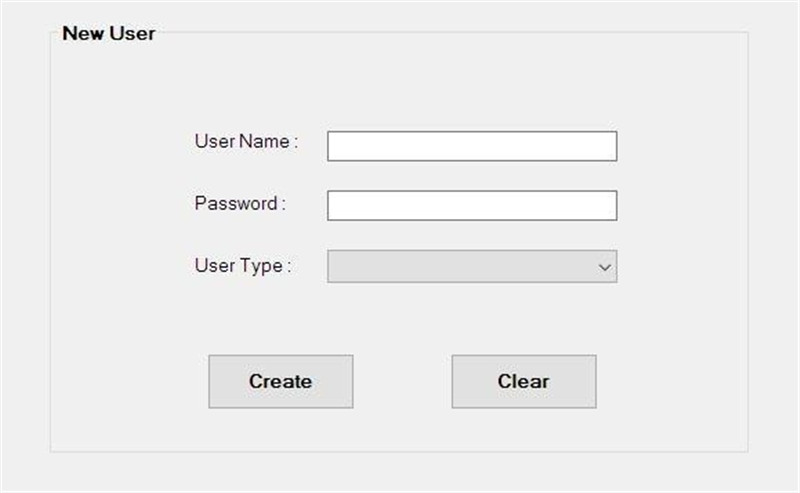

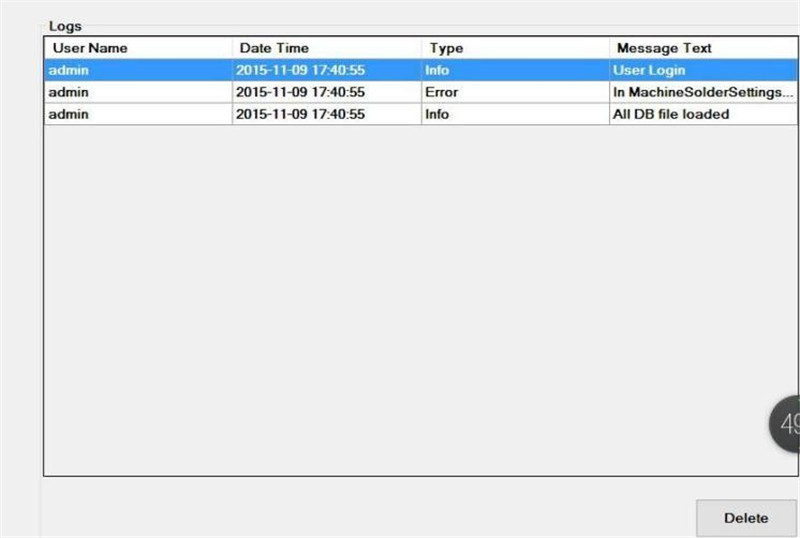

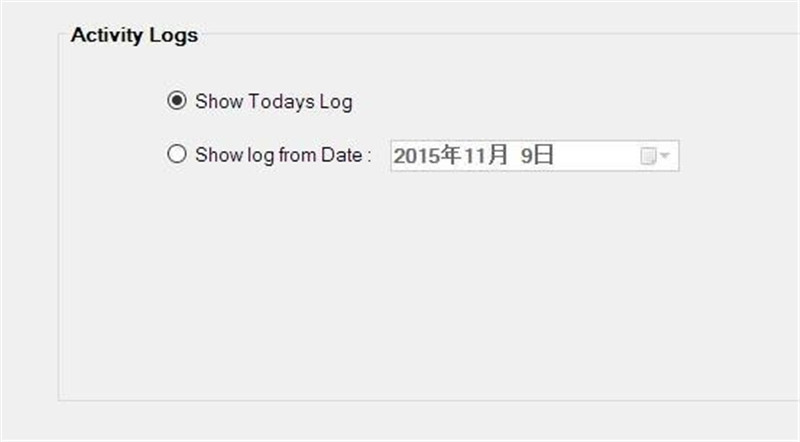

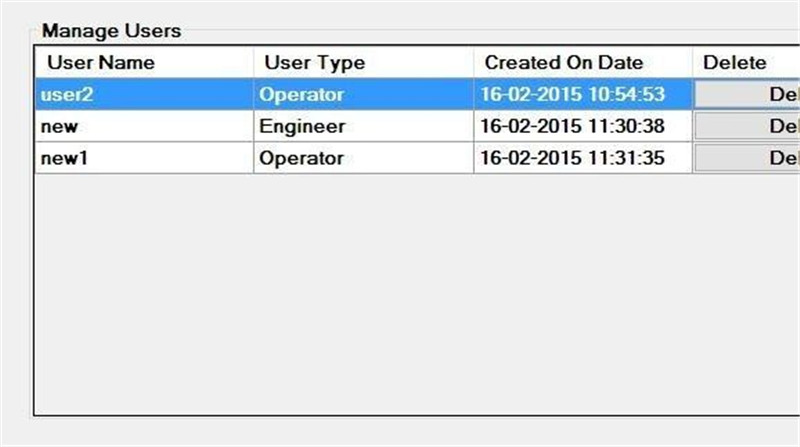

Ngomsebenzi we-LOG, hlinzeka ngezinga elingu-3 lokufaka isofthiwe enamalungelo ahlukene.Ngaleso sikhathi, ingarekhoda ukusebenza komshini ne-alamu.

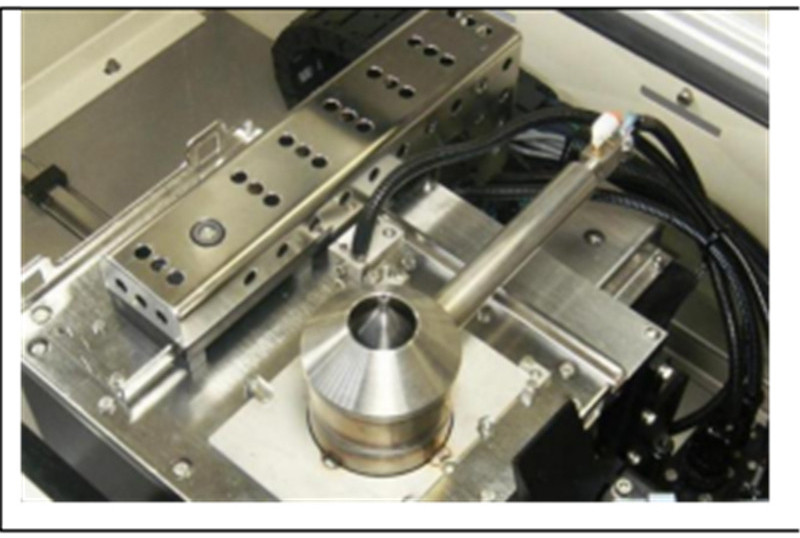

Ingxenye2: Uhlelo Lokunyakaza

Ithebula elinyakazayo laklanywa ngokusekelwe kumqondo wokukhanyisa.

I-Panasonic servo motor & driver ihlinzeka ngamandla okushayela azinzile, isikulufa se-screw pole & ne-linear guild rail ukuze uthole isiqondiso.Isikhundla esiyigugu, umsindo omncane, ukunyakaza okuzinzile.

Ngepuleti elivikela uthuli ngenhla kwetafula elinyakazayo, ukuze ugweme ukuguquguquka noma ukwehla kwe-solder ukulimaza isikulufu sebhola.

Ingxenye 3: Isistimu Yokuguquguquka

Okujwayelekile kufakwe i-jet valve ukuze uthole umphumela oguquguqukayo oyigugu onechashaza elincane elishintshashintshayo.I-Flux ifakwe ithangi lokucindezela lepulasitiki le-PP, qiniseka ukuthi ingcindezi izinzile ngaphandle kokuthonywa inani lokugeleza.

Ingxenye 4: Preheat

Ukushisa kwangaphambili okuphansi kufakwe emshinini ojwayelekile, Indawo iyalungiseka.

Isilinganiso sokushisa sishintshwa yi-PC, ukusuka ku-0 ---100%

Ingxenye 5: Imbiza Esoda

Izinga lokushisa le-solder, izinga lokushisa le-N2, ukuphakama kwegagasi, ukulinganiswa kwamagagasi njll konke okukwazi ukusetha isofthiwe.

Ibhodwe le-solder lenziwe nge-Ti, hhayi ukuvuza.Ine-heater yensimbi ngaphandle, ishisa futhi ishisa ngokushesha.

Ibhodwe le-solder lifakwe intambo ngesixhumi esisheshayo.Uma ushintsha ibhodwe le-solder ngaphandle kokufakwa kabusha kwezintambo okudingekayo, vele uxhume futhi udlale.

Isistimu yokushisa ye-inthanethi ye-N2, ukumanzisa i-solder kahle futhi yehlise amanyela e-solder.Ngokuhlola izinga le-solder ne-alamu.